the Tantalum-Niobium International Study Center (T.I.C.) : Tantalum capacitors in 5G : About Tantalum

An international, non-profit association founded in 1974 under Belgian law.

- Metals: Tantalum (Ta)

- Read 446 Times

- Metals: Tantalum (Ta)

- Industries : ALL, Manufacturing

Tantalum capacitors in 5G

This article first appeared in Bulletin #184, the quarterly journal of the T.I.C. It was written by Dr Tomas Zednicek of the European Passive Components Institute (EPCI) and based on a presentation given at the T.I.C.’s 61st General Assembly.

All views and opinions in this article are those of the author and not the T.I.C.

Contact the author: tom@passive-components.eu; www.passive-components.eu

Introduction

Tantalum capacitors offer excellent stability in harsh conditions, high energy and power volumetric efficiency and low parametric shift with lifetime, properties which make them ideal in several applications for the fifth generation (5G) of telecommunications (telecom) equipment. 5G telecom networks are forecast to rapidly become the next standard, providing faster data and better connections for smart phones, industrial applications, autonomous vehicles and smart cities.

The result is that 5G phone networks are creating an exponential increase of global data traffic and mobile data that the electronic hardware and infrastructure must support.

For many years previous generations of telecom base stations, switchers and other internet networking hardware have been using tantalum capacitors due to their long life, stability and reliability in various applications, including for DC/DC converter filtering and coupling/decoupling. The hardware has a typical lifetime of 12-15 years that mostly excludes conventional aluminium electrolytic capacitors from bulk capacitance applications.

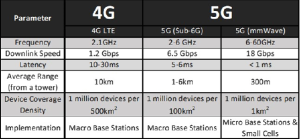

A short comparison between 4G and 5G

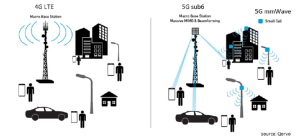

What is the difference between 5G and the current telecom system (4G)? The current system of equipment, called LTE, is capable of communicating much faster than, but remained recognisable to, previous generations of equipment. However, 5G is different. The aims of the new system are similar to previous generations – increased bandwidth, better connections, a higher data handling capability, increased speed – but to achieve them a higher frequency will be used and this requires a step change in equipment.

There are limitations when using higher frequencies, in particular a much smaller working range. For example, to achieve very high speed processing on the highest 5G frequencies (6-60 GHz) the range could be just 300m from the base station tower; a far smaller range than a 4G tower. Therefore, the 5G system will not only take over the existing 4G towers, but will also require many smaller additional towers to be constructed too, to capture the full potential of this new technology to create smart cities.

It is forecast that the new 5G system in smart cities will radically change the nature of generators and customers of mobile data since autonomous vehicles generate and use vastly more data than the total requirements of smart phones. In fact, the amount of data for a single autonomous (self-driving) vehicle could be over 4,000 GB per day.

Consequences on a component level

5G mmWave component requirements will include small dimensions, stable parameters in a wide range of operating temperatures and/or harsh environments, and long term reliability. It should also possess small dimensions. The high stability of electrical parameters and long term reliability are exactly what is required, while an additional benefit is the low profile design which supports small applications.

| Ta Capacitors Key Features | Functionality | Circuit Benefit |

|---|---|---|

| High Stability of Electrical Parameters | Stability of parameters in harsh environment | Wide operating temperature; Stable performance at various working conditions (VAC, VDC, frequency) |

| Long Term Reliability | Long term reliable operation | |

| High Volumetric Efficiency | High energy density in small size and low profile | Small size SMPS output filtering; Battery Back-Up |

| Battery back-up; high energy bank / local storage |

Tantalum capacitors in telecom equipment: GaN semiconductors for 5G base stations

Another challenge related to the next generation of electronics for telecom base stations is an evolution from silicon semiconductors to gallium nitride (GaN) semiconductors. Compared with existing technologies (silicon LDMOS and gallium arsenide (GaAs)), GaN devices meet the requirements of 5G high-frequency telecom networks, offering higher switching frequency, higher efficiency and supply higher power in a smaller, thinner design. These units use tantalum capacitors which are capable of meeting the demanding performance requirements (see Bulletin #175 for a more in-depth discussion of GaN)

Rack design for 4G and 5G base station circuit boards

On boards designed in 2014 by Ericsson and Nokia for use in a typical 4G base station there were respectively 58 and 115 tantalum capacitors. This included their use on the data handling board, system control power source, antenna control and the communication board.

While it may appear tantalum capacitors were well established on 4G boards, in 2016 cost-cutting by telecom equipment manufacturers saw the use of tantalum capacitors reduced considerably. Nokia Siemens even created a version containing no tantalum capacitors at all; on the power supply board tantalum capacitors were replaced by aluminium capacitors, while on the main CPU tantalum capacitors had been replaced by ceramic capacitors.

Will 5G boards use tantalum capacitors?

Most likely, yes, they will. The combination of low profile, high capacitance density and reliability in harsh environments makes tantalum capacitors a viable design choice. Although teardowns of the 5G hardware designs themselves have not been made public at time of writing, the latest designs for small 4G base stations by Huawei include at least 8 low-profile “D” tantalum capacitors and it is expected that the first generation of 5G base stations will follow a very similar design.

Conclusion

Tantalum capacitors have been part of telecom base station designs for many years and look set to remain so for years to come. While it is technically possible to create a 4G base station which doesn’t use any tantalum capacitors, the far more demanding operating requirements of 5G base stations mean that they will use tantalum capacitors. As the next generation of telecom networks are constructed there will be an increase in the consumption of tantalum capacitors in this application on both the main circuit boards and the GaN RF power amplifier.

For a list of references and further information on this subject please visit www.passive-components.eu.

- Author: Dr Tomas Zednicek of the European Passive Components Institute (EPCI) and based on a presentation given at the T.I.C.’s 61st General Assembly.

- Published Date: 01/01/2021

- The T.I.C. was established in response to concerns within the tantalum industry regarding the lack of useful information on tantalum source materials. The initial purpose of the T.I.C. was to spread information about tantalum and to promote the common interest and welfare of the producers, especially with public and private authorities, organisations and agencies. Since its foundation, the T.I.C. has grown to encompass niobium and all stages of the tantalum/niobium supply chains.

Advancing sustainability, technology, and industry collaboration since 1974.

Driving Global Innovation in Tantalum and Niobium

Connecting global innovators in tantalum and niobium, driving advancements from raw materials to cutting-edge applications.

- Supporting over 90 members across 30 countries.

- Promoting cutting-edge research and development.

- Facilitating a global network of professionals.