Valuation basis

The T.I.C. as an international association is not allowed to gather data on nor discuss prices, forecasting or future trends, as this would be against our Charter and may raise

The T.I.C. as an international association is not allowed to gather data on nor discuss prices, forecasting or future trends, as this would be against our Charter and may raise

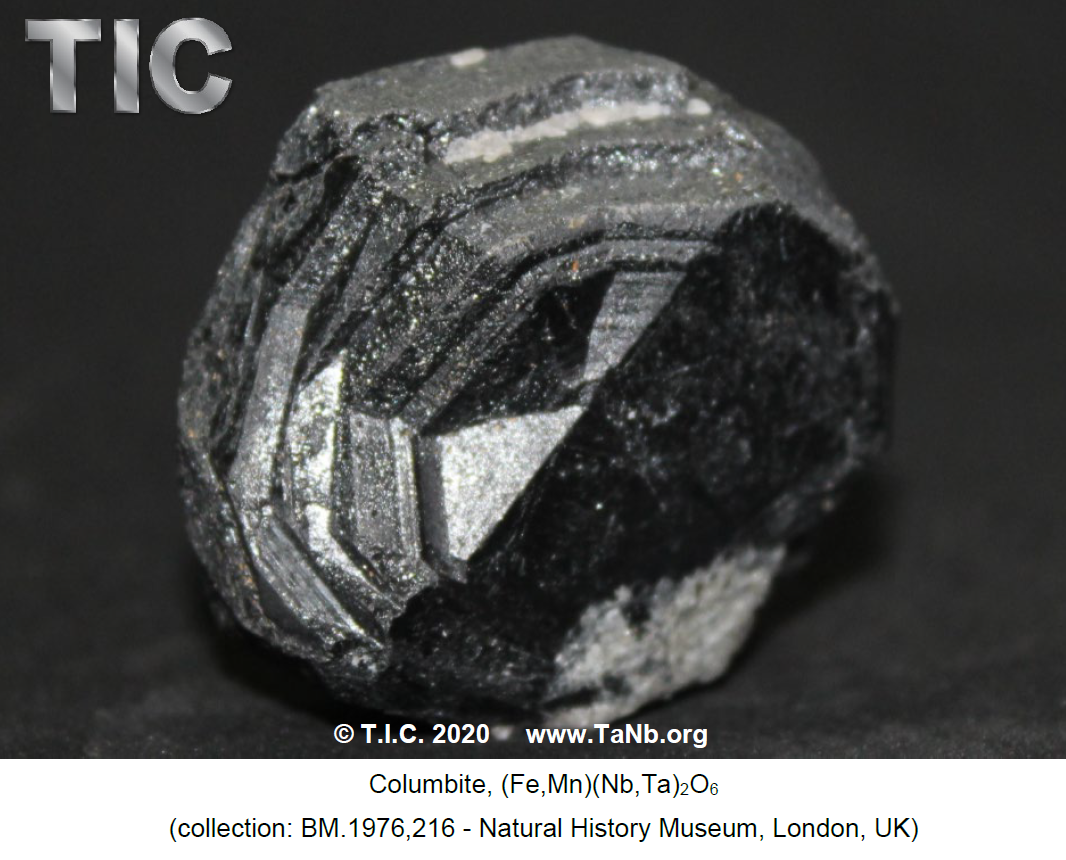

Niobium was the first of these two elements to be discovered. In 1801, Charles Hatchett (1765-1847), an English chemist, analysed a specimen of an unknown mineral from the collection of

Tantalum and Niobium: Deposits, Resources, Exploration Methods and Market (Simandl et al, 2018)

“Much ado about tantalum” by Richard Burt (2016)

British Geological Survey (BGS) profile on niobium and tantalum

In 2013/2014 Ulric Schwela, T.I.C.’s then Technical Officer, visited ASM mine sites in Burundi, DRC and Rwanda. These photographs show typical tantalite ASM processes, although in reality operations vary considerably.

Tantalum capacitors offer excellent stability in harsh conditions, high energy and power volumetric efficiency and low parametric shift with lifetime, properties which make them ideal in several applications for the

Superalloys are high-performance alloys known for their high melting temperatures, strength, and resistance to wear in corrosive and oxidising environments. They are primarily used in the hottest parts of gas

Tantalum is widely used in electronic capacitors for smartphones, automotive systems, and wind turbines. It also enhances cutting tools, SAW filters, optical lenses, chemical process equipment, and medical devices like

The extraction and refining of tantalum, including its separation from niobium in various tantalum-containing mineral concentrates, is generally accomplished by treating the ores with a mixture of hydrofluoric and sulfuric